| Product specifications | |

| Size | 200A ~ 1,000A |

|---|---|

| |

| Product Use | Various water and sewage facilities requiring filtration |

| Product Features |

|

| Product Certification |

|

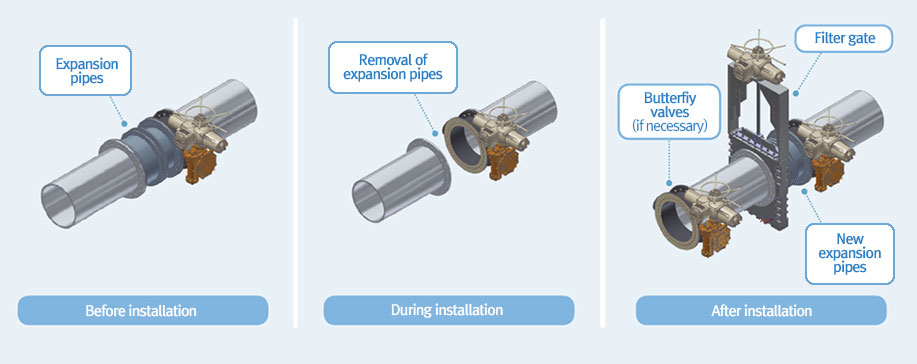

| Fitting Method | Flange |

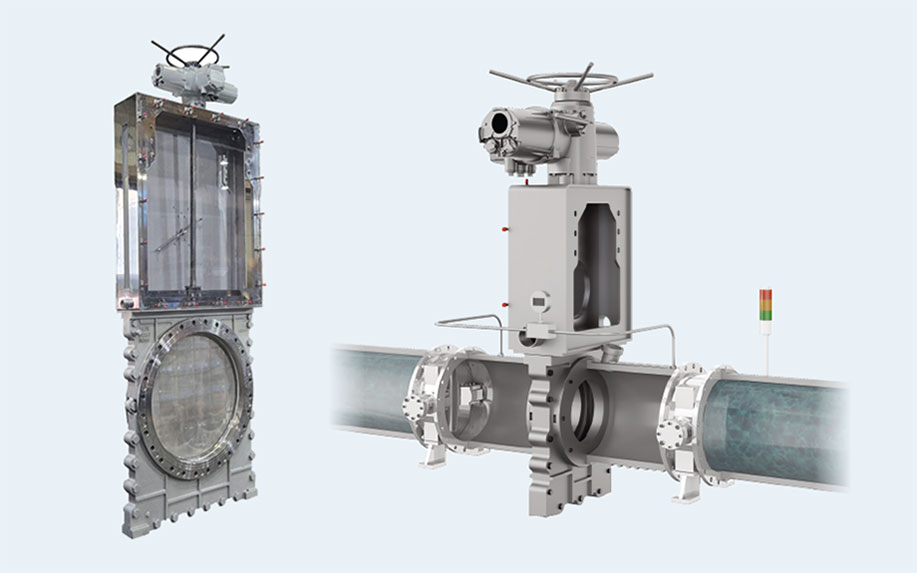

| Drive unit | Manual, Electric |

| Patent |

|

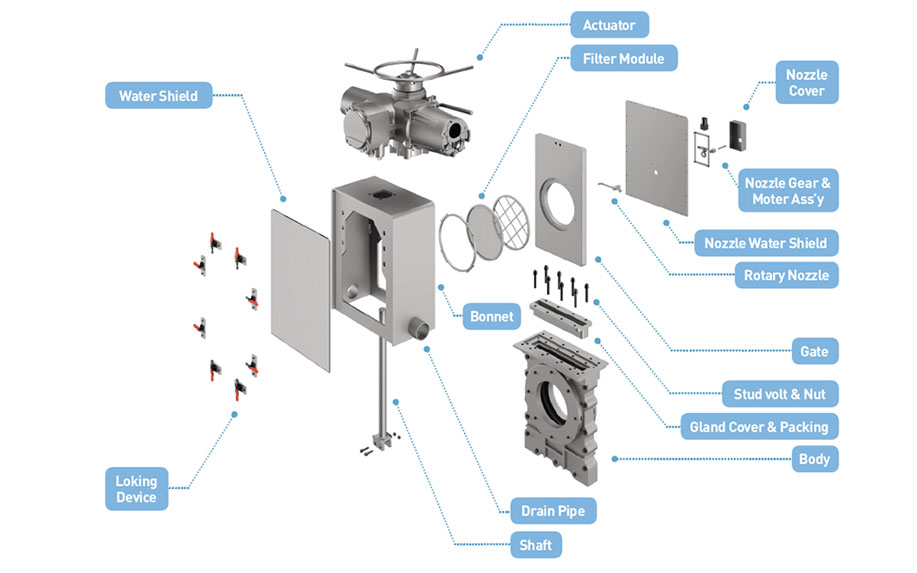

| Designation | Detail |

| Body |

|

|---|---|

| Gland Cover & Packing |

|

| Stud Bolt & Nut |

|

| Gate |

|

| Filter module |

|

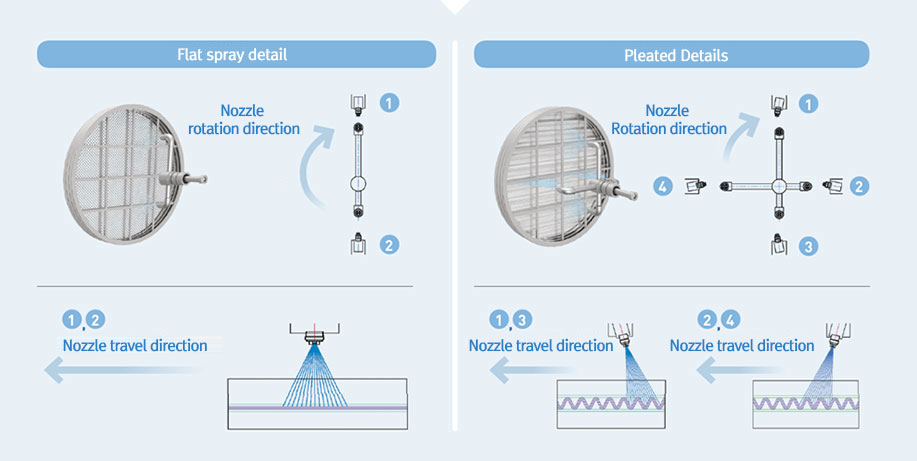

| Nozzle Gear & Moter Ass'y |

|

| Rotary Nozzle |

|

| Drain Pipe |

|

| Shaft |

|

| Bonnet |

|

| Actuator |

|

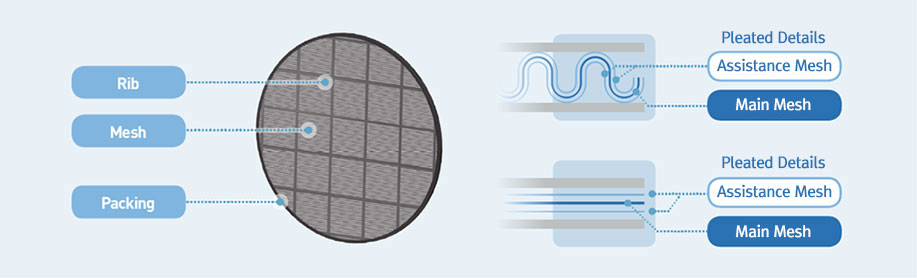

Rib |

by sludge in the fluid. |

|---|---|

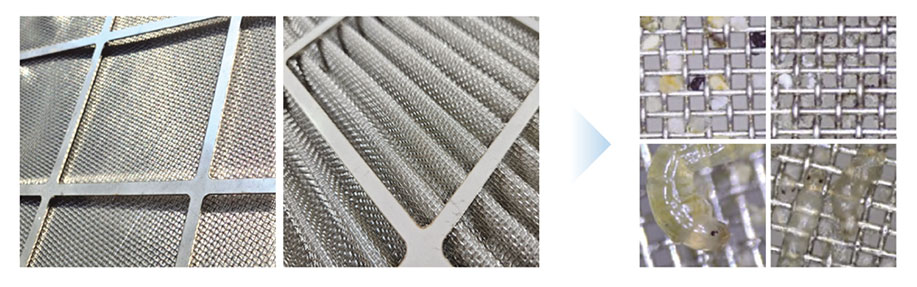

| Main Mesh |

|

| Assistance Mesh |

|

|---|---|

| Packing |

|